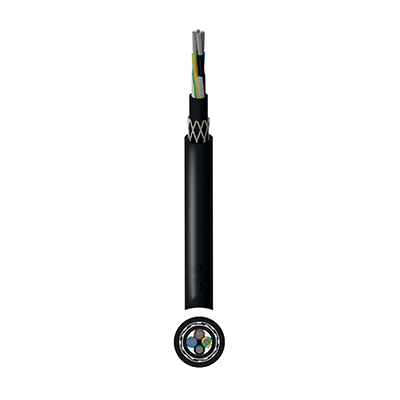

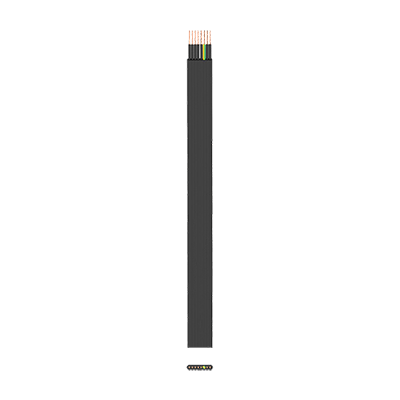

PUR-HF Festoon Cable Description

PUR-HF Festoon Cable uses a halogen-free flame-retardant polyurethane (PUR-HF) jacket with excellent resistance to mechanical stress, oil, UV radiation, heat and humidity. It is commonly used in overhead cranes, container cranes and other material handling equipment.

PUR-C-HF EMC Festoon Cable is an electromagnetically shielded version of PUR-HF cable, both cables are suitable for travel speeds in festoon systems, horizontal drums and chain systems.

PUR-HF Trommel Cable is suitable for mechanical screening machines, where its wedge-shaped steel wire cylindrical drum is used to lift, aerate and screen materials.

PUR-HF Spreader Reel Cable is designed for vertical winding applications, especially for use with booms on lifting equipment. Able to resist mechanical stress such as torsion, tension and torque, it is suitable for high speed and high load operation.

PUR-HF Festoon Cable Construction

| PUR-HF Trommel Cable | PUR-HF Festoon Chain Cable | PUR-HF Spreader Reel Cable | PUR-C-HF EMC Festoon Cable | |

|---|---|---|---|---|

| VOLTAGE | 0.6/1kV | |||

| CONDUCTOR | Class 5 flexible stranded Copper | |||

| INSULATION | Halogen Free compound | |||

| LAY UP | Central strength member, cores in concentric layers | |||

| INNER SHEATH | PUR-HF (Polyurethane Halogen Free Flame Retardant) | - | PUR-HF (Polyurethane Halogen Free Flame Retardant) | |

| SCREEN | - | TCWB (Tinned Copper Wire Braid) - minimum 80% coverage | ||

| BRAID | Anti-twist textile braid | - | Anti-twist aramid yarns | - |

| OUTER SHEATH | PUR-HF (Polyurethane Halogen Free Flame Retardant) | |||

PUR-HF Festoon Cable Characteristics

| PUR-HF Trommel Cable | PUR-HF Festoon Chain Cable | PUR-HF Spreader Reel Cable | PUR-C-HF EMC Festoon Cable | |

|---|---|---|---|---|

| Temperature Rating | Fixed installation: -50°C to +90°C Mobile operation: -40°C to +90°C | Fixed installation: -50°C to +80°C Mobile operation: -40°C to +80°C | Fixed installation: -50°C to +90°C Mobile operation: -40°C to +90°C | Fixed installation: -50°C to + 80°C Mobile operation: -40°C to +80°C |

| Minimum Bending Radius | Fixed : 6 x Overall Diameter Mobile: 8 x Overall Diameter |

|||

| Maximum Tensile Load | 20 N/mm² | 15 N/mm² | 30 N/mm² | 15 N/mm² |

| Maximum Torsion | ±25º/m | |||

| Travel Speed | Festoon systems: up to 200m/min Reeling applications: up to 200m/min horizontal | Festoon systems: up to 200m/min Reeling applications: up to 60m/min horizontal Chain systems: up to 200 N/mm | Festoon Systems Up to 240m/min Reeling Application: Up to 240m/min horiz. / Up to 180m/min vertica | Festoon Systems: Up to 200m/min Reeling: Up to 60m/min horiz. / Up to 200m/min vertical Chain Systems: Up to 200m/min vertical |

PUR-HF Festoon Cable Applications

- Festoon Systems:

- Used to supply power and control signals to moving equipment like cranes, hoists, and monorails.

- Cable Drag Chains:

- Suitable for use in cable carriers, protecting cables in moving machinery.

- Machine Tools:

- Used in various machine tool applications where flexibility and reliability are crucial.

- Conveyor Systems:

- Provide power and control for conveyor belts and other material handling systems.

- Other Moving Applications:

- Also used in applications like jib cranes, port cranes, and other material handling equipment.

- PUR-HF Trommel Cable

- PUR-HF Festoon Chain Cable

- PUR-HF Spreader Reel Cable

- PUR-C-HF EMC Festoon Cable

| NO. OF CORES | NOMINAL CROSS SECTIONAL AREA mm² | NOMINAL OVERALL DIAMETER mm | NOMINAL WEIGHT kg/km |

|

|---|---|---|---|---|

| Minimum | Maximum | |||

| 4 | 1.5 | 10 | 11.4 | 146 |

| 4 | 2.5 | 11.1 | 12.3 | 202 |

| 4 | 4 | 12.2 | 13.6 | 280 |

| 4 | 6 | 13.3 | 14.9 | 370 |

| 4 | 10 | 17.4 | 18.9 | 610 |

| 4 | 16 | 20 | 22.1 | 852 |

| 4 | 25 | 22.9 | 25.3 | 1228 |

| 4 | 35 | 28.5 | 30.2 | 1760 |

| 5 | 1.5 | 10.6 | 11.8 | 172 |

| 5 | 2.5 | 11.8 | 13 | 228 |

| 5 | 4 | 13.1 | 14.5 | 324 |

| 5 | 6 | 16.4 | 17.6 | 476 |

| 5 | 10 | 18.7 | 20.5 | 724 |

| 5 | 16 | 21.7 | 24.2 | 1030 |

| 7 | 1.5 | 12.1 | 13.5 | 220 |

| 7 | 2.5 | 13.5 | 14.7 | 316 |

| 12 | 1.5 | 15.4 | 17 | 356 |

| 12 | 2.5 | 18.5 | 20.5 | 552 |

| 18 | 1.5 | 16.9 | 18.4 | 472 |

| 18 | 2.5 | 19.2 | 20.4 | 664 |

| 24 | 1.5 | 19 | 20.9 | 595 |

| 24 | 2.5 | 21.2 | 23.6 | 884 |

| 30 | 1.5 | 21.5 | 23 | 740 |

| 30 | 2.5 | 25.4 | 28.2 | 1086 |

| 36 | 2.5 | 27 | 30 | 1400 |

| 42 | 1.5 | 25 | 28.5 | 932 |

| NO. OF CORES | NOMINAL CROSS SECTIONAL AREA mm² | NOMINAL OVERALL DIAMETER mm | NOMINAL WEIGHT kg/km |

|

|---|---|---|---|---|

| Minimum | Maximum | |||

| 3 | 1.5 | 6.5 | 7.5 | 118 |

| 3 | 2.5 | 8.1 | 9.1 | 130 |

| 4 | 1.5 | 8.1 | 9.1 | 124 |

| 4 | 2.5 | 9.2 | 10.2 | 160 |

| 4 | 4 | 10.3 | 11.5 | 234 |

| 4 | 6 | 12.1 | 13.2 | 320 |

| 4 | 10 | 15 | 16.2 | 520 |

| 4 | 16 | 17.7 | 18.9 | 750 |

| 4 | 25 | 21.1 | 22.5 | 1160 |

| 4 | 35 | 25.8 | 27.4 | 1660 |

| 4 | 50 | 31 | 33 | 2400 |

| 5 | 2.5 | 9.8 | 11 | 180 |

| 5 | 4 | 11.6 | 12.7 | 280 |

| 5 | 6 | 14 | 15.2 | 420 |

| 5 | 10 | 16.2 | 17.5 | 630 |

| 5 | 16 | 19.4 | 20.6 | 930 |

| 5 | 25 | 23.2 | 24.5 | 1380 |

| 7 | 1.5 | 9 | 10 | 220 |

| 7 | 2.5 | 11.5 | 12.7 | 250 |

| 12 | 1.5 | 14.3 | 15.5 | 320 |

| 12 | 2.5 | 16.5 | 17.7 | 470 |

| 18 | 1.5 | 14.5 | 15.7 | 380 |

| 18 | 2.5 | 16.7 | 17.9 | 580 |

| 24 | 1.5 | 16.5 | 17.8 | 500 |

| 24 | 2.5 | 19.2 | 20.4 | 770 |

| 30 | 1.5 | 19.6 | 21 | 680 |

| 30 | 2.5 | 24.9 | 26.5 | 1040 |

| NO. OF CORES | NOMINAL CROSS SECTIONAL AREA mm² | NOMINAL OVERALL DIAMETER mm | NOMINAL WEIGHT kg/km |

|

|---|---|---|---|---|

| Minimum | Maximum | |||

| 18 | 2.5 | 22 | 26 | 1100 |

| 24 | 2.5 | 26.4 | 29.4 | 1400 |

| 30 x 5 x 6 | 2.5 + 2.5 | 30.2 | 34.2 | 1600 |

| 36 x 6 x 6 | 2.5 + 2.5 | 34.7 | 38.5 | 2080 |

| 36 | 2.5 | 30.2 | 33 | 1850 |

| 42 x 7 x 6 | 2.5 + 2.5 | 37.8 | 41.8 | 2280 |

| 44 | 2.5 | 32.5 | 35.5 | 1950 |

| 8 x 6 | 2.5 | 42.7 | 45.1 | 2620 |

| 54 x 9 x 6 | 2.5 + 2.5 | 43.8 | 48.8 | 2800 |

| NO. OF CORES | NOMINAL CROSS SECTIONAL AREA mm² | NOMINAL OVERALL DIAMETER mm | NOMINAL WEIGHT kg/km |

|

|---|---|---|---|---|

| Minimum | Maximum | |||

| 4 | 1.5 | 10.8 | 12 | 232 |

| 4 | 2.5 | 12.1 | 13.2 | 248 |

| 4 | 6 | 15.1 | 16.3 | 426 |

| 4 | 10 | 18.4 | 19.6 | 636 |

| 4 | 16 | 21.2 | 22.5 | 932 |

| 4 | 25 | 24.5 | 26.2 | 1400 |

| 4 | 35 | 29.6 | 31.6 | 1820 |

| 4 | 50 | 35.1 | 37.6 | 2510 |

| 5 | 1.5 | 10.9 | 12.1 | 260 |

| 5 | 2.5 | 12.8 | 14 | 268 |

| 5 | 4 | 13.8 | 15 | 344 |

| 7 | 1.5 | 10.9 | 12.1 | 270 |

| 12 | 1.5 | 15 | 16.2 | 360 |

| 12 | 2.5 | 17 | 18.8 | 520 |

| 18 | 1.5 | 15.4 | 17.2 | 424 |

| 18 | 2.5 | 17.5 | 19.2 | 630 |

Why Huadong Cable

Our vision is to become an internationally renowned brand in the field of cables; customer satisfaction, employee promotion, and corporate development are our service tenets; high standards, globalization, and building an international brand are our business philosophy.

About HuaDong

Henan Huadong Cable Co., Ltd. was founded in 1999 which is a joint-stock national high-tech enterprise integrating scientific research, industry and trade. Huadong Cable is deeply integrated into the "Belt and Road" construction and exports to more than 130 countries around the world, including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

HuaDong Technology

Huadong Cable focuses on technology research and development which has 60 professional personnel with senior professional titles, and has more than 100 invention and utility model patents. Huadong has a team of experienced technical engineers to ensure the quality of cables.

Main Products

Our main products : marine cables, power cables, overhead cables, fireproof cables, low-smoke halogen-free cables, rubber cables, high temperature resistant cables, instrument and control cables, solar cables and other products.

ISO, SGS, BV CERTIFICATION; TECHNICAL PATENTS AND PRODUCT CERTIFICATION

TECHNICAL AND CLIENTS

Export Countries

Technical Patents

Annual Productivity

Employees