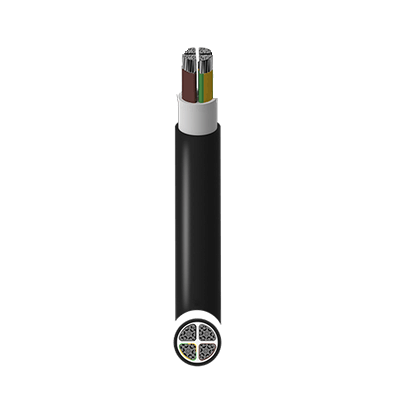

NA2XH Cable Description

NA2XH cables are suitable for use in soil, pipelines, racks, dry and wet environments, to avoid mechanical damage, and the cables will not be subjected to mechanical tensile stress. They are used in refineries, hotels, schools, tunnels, high-rise buildings, hospitals, power plants, data processing centers, densely populated commercial centers, etc., where there is a risk of fire.

The cables comply with IEC 60502-1 standards and are widely used for fixed installations in Europe, the Middle East, and Africa.

NA2XH Cable Construction

| NA2XH 0.6/1kV | NA2XH 1.8/3kV | |

|---|---|---|

| CONDUCTOR | RM: Class 2 stranded SE: Class 1 solid sector - shaped or stranded SM: Class 2 sector - shaped | Class 2 Stranded Plain Aluminium Circular Compact Conductor |

| INSULATION | XLPE (Cross-Linked Polyethylene) | |

| SHEATH | LSZH (Low Smoke Zero Halogen) | |

NA2XH Cable Characteristics

| NA2XH 0.6/1kV | NA2XH 1.8/3kV | |

|---|---|---|

| Voltage Rating Uo/U (Um) | AC: 0.6/1 (1.2)kV DC: 0.75/1.5 (1.8)kV | 1.8/3 (3.6)kV |

| Temperature Rating | Fixed: -40°C to +90°C | Maximum Conductor Operating Temperature: +90ºC Maximum Conductor Temperature During S.C: +250°C |

| Minimum Bending Radius | Single core: 15 x overall diameter Multi-core: 12 x overall diameter | 15 x Overall Diameter |

NA2XH Cable Benefits

- Safety: Halogen-free and flame-retardant properties reduce the risk of fire and toxic gas emissions.

- Durability: XLPE insulation provides long-term reliability and performance.

- Versatility: Suitable for various installation environments and applications.

NA2XH Cable Diagram

- NA2XH 0.6/1kV

- NA2XH 1.8/3kV

| NO. OF CONDUCTOR | NOMINAL CROSS SECTIONAL AREA mm² | CONDUCTOR TYPE | NOMINAL OVERALL DIAMETER mm | NOMINAL WEIGHT kg/km |

|---|---|---|---|---|

| 1 | 25 | RM | 9.9 | 132 |

| 1 | 35 | RM | 11 | 166 |

| 1 | 50 | RM | 12.5 | 211 |

| 1 | 70 | RM | 14.1 | 283 |

| 1 | 95 | RM | 16.1 | 376 |

| 1 | 120 | RM | 17.5 | 456 |

| 1 | 150 | RM | 19.6 | 560 |

| 1 | 185 | RM | 21.8 | 697 |

| 1 | 240 | RM | 24 | 878 |

| 1 | 300 | RM | 26.7 | 1073 |

| 1 | 400 | RM | 29.7 | 1347 |

| 1 | 500 | RM | 33.1 | 1705 |

| 1 | 630 | RM | 42.8 | 2705 |

| 1 | 800 | RM | 47.9 | 3420 |

| 3 | 16 | RM | 16.3 | 364 |

| 3 | 25 | RM | 19.6 | 530 |

| 3 | 35 | RM | 22.1 | 684 |

| 3 | 35 | SE | 19 | 486 |

| 3 | 50 | SM | 22.4 | 655 |

| 3 | 50 | SE | 21.2 | 622 |

| 3 | 70 | SM | 26.1 | 903 |

| 3 | 70 | SE | 25.2 | 859 |

| 3 | 95 | SM | 29.1 | 1174 |

| 3 | 95 | SE | 27.8 | 1115 |

| 3 | 120 | SM | 32.2 | 1446 |

| 3 | 120 | SE | 30.8 | 1379 |

| 3 | 150 | SM | 36.2 | 1780 |

| 3 | 150 | SE | 33.9 | 1685 |

| 3 | 185 | SM | 40.1 | 2197 |

| 3 | 185 | SE | 37.6 | 2089 |

| 3 | 240 | SM | 44.9 | 2782 |

| 3 | 240 | SE | 41.8 | 2634 |

| 3 | 70 + 35 | SM+SM | 28.3 | 1044 |

| 3 | 120 + 70 | SM+SM | 35.1 | 1704 |

| 3 | 150 + 70 | SM+SM | 39.7 | 2065 |

| 3 | 185 + 95 | SM+SM | 43.7 | 2563 |

| 3 | 240 + 120 | SM+SM | 49.1 | 3237 |

| 4 | 25 | RM | 21.7 | 636 |

| 4 | 35 | SM | 22.4 | 649 |

| 4 | 35 | SE | 21.6 | 623 |

| 4 | 50 | SM | 25.4 | 845 |

| 4 | 50 | SE | 24.6 | 810 |

| 4 | 70 | SM | 29.7 | 1178 |

| 4 | 70 | SE | 28.8 | 1126 |

| 4 | 95 | SM | 33.3 | 1538 |

| 4 | 95 | SE | 32.1 | 1467 |

| 4 | 120 | SM | 37.2 | 1903 |

| 4 | 120 | SE | 35.5 | 1817 |

| 4 | 150 | SM | 41.3 | 2328 |

| 4 | 150 | SE | 39.4 | 2223 |

| 4 | 185 | SM | 45.7 | 2874 |

| 4 | 185 | SE | 43.4 | 2750 |

| 4 | 240 | SM | 51.2 | 3646 |

| 4 | 240 | SE | 48 | 3465 |

| 5 | 25 | RM | 23.9 | 763 |

| 5 | 35 | RM | 27 | 986 |

| 5 | 50 | RM | 31.3 | 1309 |

| 5 | 70 | RM | 35.8 | 1771 |

| 5 | 95 | SM | 36.5 | 1891 |

| 5 | 120 | SM | 39.2 | 2306 |

| 5 | 150 | SM | 45.4 | 2865 |

| 5 | 185 | SM | 50.1 | 3534 |

| 5 | 240 | SM | 55.2 | 4482 |

| NO. OF CORES | NOMINAL CROSS SECTIONAL AREA mm² | NOMINAL INSULATION THICKNESS mm | NOMINAL SHEATH THICKNESS mm | NOMINAL OUTER DIAMETER mm | NOMINAL WEIGHT kg/km |

|---|---|---|---|---|---|

| 1 | 16 | 2 | 1.4 | 14 | 240 |

| 1 | 25 | 2 | 1.4 | 15.1 | 285 |

| 1 | 35 | 2 | 1.4 | 16.2 | 330 |

| 1 | 50 | 2 | 1.4 | 17.5 | 390 |

| 1 | 70 | 2 | 1.5 | 19.3 | 490 |

| 1 | 95 | 2 | 1.5 | 20.8 | 580 |

| 1 | 120 | 2 | 1.6 | 22.4 | 690 |

| 1 | 150 | 2 | 1.6 | 24.6 | 810 |

| 1 | 185 | 2 | 1.7 | 25.7 | 940 |

| 1 | 240 | 2 | 1.8 | 28.3 | 1140 |

| 1 | 300 | 2 | 1.8 | 30.6 | 1355 |

| 1 | 400 | 2 | 1.9 | 33.5 | 1660 |

| 1 | 500 | 2.2 | 2 | 38.2 | 2135 |

| 1 | 630 | 2.4 | 2.2 | 42.5 | 2700 |

| 1 | 800 | 2.6 | 2.3 | 47.9 | 3420 |

| 1 | 1000 | 2.8 | 2.4 | 54.8 | 4255 |

Why Huadong Cable

Our vision is to become an internationally renowned brand in the field of cables; customer satisfaction, employee promotion, and corporate development are our service tenets; high standards, globalization, and building an international brand are our business philosophy.

About HuaDong

Henan Huadong Cable Co., Ltd. was founded in 1999 which is a joint-stock national high-tech enterprise integrating scientific research, industry and trade. Huadong Cable is deeply integrated into the "Belt and Road" construction and exports to more than 130 countries around the world, including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

HuaDong Technology

Huadong Cable focuses on technology research and development which has 60 professional personnel with senior professional titles, and has more than 100 invention and utility model patents. Huadong has a team of experienced technical engineers to ensure the quality of cables.

Main Products

Our main products : marine cables, power cables, overhead cables, fireproof cables, low-smoke halogen-free cables, rubber cables, high temperature resistant cables, instrument and control cables, solar cables and other products.

ISO, SGS, BV CERTIFICATION; TECHNICAL PATENTS AND PRODUCT CERTIFICATION

TECHNICAL AND CLIENTS

Export Countries

Technical Patents

Annual Productivity

Employees